Reflex Level Gauge with Bridle for GWR Level Transmitter

Level Indicators

Level indicators are devices used in the measurement of level of fluids at various industrial applications. These devices are used to determine the level of liquid in tanks, drums. pressure vessels etc..

Types of Level Indicators

There are many level indicators to suit the needs of different applications. Normally, fluids are used in many forms in highly commercial industries. Without proper devices it will be very difficult to find the quantity and level of fluid stored. Also, in certain situations where the nature of fluid is dangerous or the place in which the liquid is stored is of such a nature that it is manually impossible to find the level, then the level indicators are of utmost importance.

How to Choose the Right Level Indicators

Depending on the type of application, the right level indicator should be selected. For example, in the process industry, tubular level indicators are used for better visual liquid level indication. If it is for non-contact type level measurement, then radar type indicators or ultrasonic type indicators are to be used.

This is a special type of application where a Magnetic level indicator application was ruled out because of the application constraint, our end user wanted a level measurement that suited their industry. Shridhan Automation came up with the application that would measure and control the liquids and give them a better visual liquid level indicator. Since Magnetic Level indicator was not applicable, Reflex gauge and an external chamber was adopted.

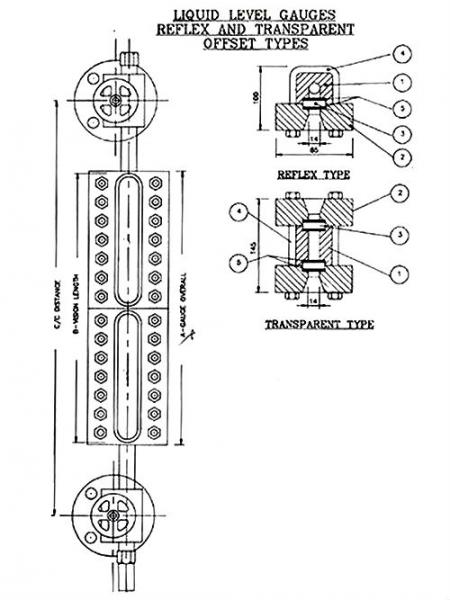

Working Principle of Reflex Glass Level Gauges

Reflex glass level gauges working principle is based on the light refraction and reflection laws. Reflex level gauges are designed to detect the difference in refractive indices of vapour and liquid and level detection and can be used in a number of process applications. Reflex gauges, also referred to as prismatic level gauges, offer a well-defined image of water levels. This reduces risks of distortions or reading areas. Because of this, a reflex level gauge can be installed in a tilt-view or vertical position to produce even greater accuracy in readings along with a much better degree of reliability, this is highly beneficial for many industries.

Applications of Reflex Level Gauges

Reflex level gauges may be applied in numerous applications to include feed water heaters, DE aerators, boiler drums, and other types of tanks.

For a reflex level gauge, within the recess of a liquid chamber and behind a single piece of glass, is the liquid column that clamps down onto the gauge body. This glass is flat on the outside and on the inside has a series of prism grooves that face the vapour and liquid space. Based on whether light enters the vapour or liquid space, it is reflected or absorbed, respectively.

Once light encounters a groove’s surface within the vapour space it reflects to the surface of the grooves on the opposite side, followed by reflecting completely back to the observation direction. During the liquid phase, light is absorbed, which creates one display for the area that is covered by liquid and another display for the area located above the liquid.

Using the prism glass, a reflex level gauge accurately measures liquid inside the vessel. When light hits the glass where there is no liquid, the prism reflects the light directly out of the gauge. Known as the "dry" area, a silver colour is displayed while the "wet" part is displayed in black. The contrasting colours create a clear delineation line that makes it easy to view the measurement.

The external chamber is a self-contained cage designed for use with our top mounting level transmitters or switches. Quality construction and a wide selection of configurations make this cage an ideal means of utilizing the power of our many technologies without mounting directly into the process vessel.

Level gauges provide a number of benefits that are industry-specific. A manufacturer like Shridhan that has specialized expertise in Manufacturing level gauges you have full assurance of enjoying optimal performance and reliability.

We understand each and every application and their advantageous to our end-users, making our products precise.

For further Application Specific Customization enquiries - Please contact us on info@shridhan.com